|

specification |

Equipment name |

UNIT |

QTY |

Unit price(Ten thousand yuan) |

Remark |

|

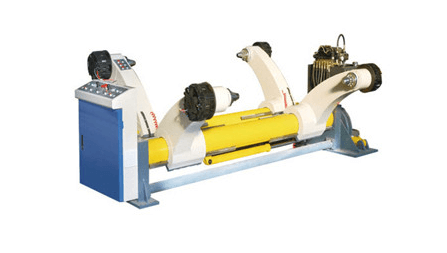

RNNJ-V5B |

Hydraulic shaftless mill roll stand |

A |

5 |

7.2 |

The spindle¢240mm,hyperbola heavy rocker,toothed chuck,multi-disc ventilated disc brakes,hydraulic drive lift,left and right translation,for medium。 Rail length6000mm,trolly used 10mm plate welding。 |

|

Paper trolly |

A |

10 |

|||

|

RNNG-1-900 |

Glossy preheat cylinder |

A |

2 |

4 |

roller¢900mm,including certificate of pressure vessel。Electromotion adjustment angle。It can adjust the paper preheat area in the range of 360°。 |

|

RNNG-1-900 |

Core paper preheat cylinder |

A |

2 |

4 |

roller¢900mm,including certificate of pressure vessel。Electromotion adjustment angle。It can adjust the paper preheat area in the range of 360°。 |

|

SF-320C |

Fingerless type single facer |

A |

2 |

26 |

Corrugated main roller¢320mm,material48CrMo alloy steel,Corrugated roller spraying hard chrome plating, surface hardness HRC58 degrees.Adopt independent gearbox,univeral joint transmission structure。Corrugated roller group exchange. PLC automatic control of glue。 |

|

RNNG-3-900 |

Triple preheater |

A |

1 |

12 |

roller¢900mm,including the certificate of pressure vessal。electromotion adjustment angle.it can adjust the paper preheat areas in the range of 360°。 |

|

GM-C |

Double glue machine |

A |

1 |

11 |

Diameter of glue roller¢269mm,Pit style textured。Frequency independent motor drive,PL Ccontrol,Machine interface touch screen display。 |

|

ZDF |

Conveyor bridge |

set |

1 |

20 |

Using channel, beam, angle and other connections, independent inverter motor drive traction to enhance delivery of paper. |

|

SM-F |

Double facer |

set |

1 |

65 |

The rack 360 mm GB channel,Chrome hot plate600 mm *16pieces,Cold segment length4m。Entrance ¢ 400mm hot cylinder so glossy Speed mention warm, hot plate contact plate design structure。PLCAutomatic control plate。Down with automatic correction, temperature display, inverter motor。 |

|

ZQS |

Thin knife slitting |

A |

1 |

6.5 |

Electric thin knife electric partial,Electric adjustment of clearance,five knives eight lines,the blade made of tungsten alloy steel。 |

|

NC-150 |

NC cutter helical knives |

A |

1 |

20 |

Full ac servo control spiral blade structure。Germany Bryant servo motor drive controller,Taiwan Eview yield 10.4 inches color touch screen display。 |

|

DMT-120 |

Paper sheet delivery and side conveyer |

A |

1 |

5 |

electric adjusted board size,pneumatic control transverse output board. |

|

ZJZ |

Glue station system |

set |

1 |

4 |

Customers -owned pipeline。Glue configuration is composed by carrier tank、main tank、storage tank、and send plastic pump、back plastic pump。 |

|

QU |

Gas source system |

A |

1 |

Including 0.6m³gas tank 1 unit。Air pump、pipeline is prepared by the customers. |

|

|

ZQ |

Steam system |

set |

1 |

4 |

Steam system components used in all GB valves。Including rotaty joint,upper and lower dispenser。traps,pressure tableand so on。Customer-owned boilers and pipes. |

|

DQ |

Electrical control cabinet system |

set |

1 |

Electronic control system:The entire line speed mechanism adopts electromagnetic speed motor。Cabinet surface paint electrostatic spray ,Wearable and beautiful.The main contactor relays using major brands. |

Main Technical Parameters and Requirements in Production Line

|

1 |

Effective width |

1800mm |

2 |

Design produce speed |

150m/min |

|||

|

3 |

Three layer work speed |

120-150m/min |

4 |

Five layer work speed |

100-130m/min |

|||

|

5 |

Seven layer work speed |

——————- |

6 |

The highest chane single speed |

100m/min |

|||

|

7 |

Longitudinal separation accuracy |

±1mm |

8 |

Cross-cutting precision |

±1mm |

|||

|

Note |

Speed the above targets required to achieve:effective width1800mm,Comply with the following standards and ensure the paper’s equipment condition 175 ℃ heating surface temperature. |

|||||||

|

Glossy paper index |

100g/㎡–180g/㎡ Ring crush index(N.m/g)≥8 (Water containing8-10%) |

|||||||

|

Core paper index |

80g/㎡–160g/㎡ Ring crush index(N.m/g)≥5.5 (Water containing8-10%) |

|||||||

|

In paper index |

90g/㎡–160g/㎡ Ring crush index(N.m/g)≥6 (Water containing8-10%) |

|||||||

|

9 |

Flute combination |

|||||||

|

10 |

Steam requirment |

The maximum pressure 16kg/cm2 |

Common pressure10-12kg/cm2 |

use4000kg/Hr |

||||

|

11 |

Electricity demand |

AC380V 50Hz 3PH |

Installed capacity≈250KW |

Prime Power≈150KW |

||||

|

12 |

Compressed air |

The maximum pressure 9kg/cm2 |

Common pressure4-8kg/cm2 |

use1m3/min |

||||

|

13 |

Space |

≈Lmin75m*Wmin10m*Hmin5m(The actual drawing to provider to provide audited prevail) |

||||||

Customer-owned section |

|

1、 steam heating system:proposal with 4000Kg / Hr of a steam boiler pressure:1.25Mpa steam pipeline。 |

|

2、 air compressed machine、air pipeline、glue conveying pipe。 |

|

3、 power supply、wires connected to the operation panel and line pipe。 |

|

4、 water sources、water pipelines、buckets and so on。 |

|

5、 Water, electricity, gas flush mounting civil foundation。 |

|

6、 Test with the base paper、corn starch (potato)、Industrial use caustic soda、borax and other material。 |

|

7、 Oil equipment、lubricating oil、hydraulic oil、lubricating grease。 |

|

8、 installation、commissioning of food, accommodation。And provide installers with the installation。 |

RNNJ-V5B Hydraulic Shaftless Mill Roll Stand

※structural feature:

★adopt hydraulic drive to complete the paper clamping, loosen, remove for the medium, translation left and right and others,the lifting of the paper adopts hydraulic drive.

★brake adjustable adopts multipoint braking system.

★every stand matched two sets paper car , and they can paper on the both sides at the same time.

※technical parameters:

1、the range of clamping paper:MAX1800mm MIN1000mm

2、clamping diameters:MAX¢1500mm MIN¢350mm

3、main shaft diameter of paper holder:¢242mm

4、gas source work pressure(Mpa):0.4—0.8Mpa

5、equipment size:Lmx4.3*Wmx1.8*Hmx1.6

6、single weight:MAX4000Kg

※Hydraulic system parameters:

1 Work pressure(Mpa):16—18Mpa

2、lifting hydraulic cyclinder:¢100×440mm

3 Claming hydraulic cyclinder:¢63×1300m

4 station motor power:3KW –380V — 50Hz

5 solenoid valve voltage:220V 50 Hz

RNNG-1-900 Glossy(core)Paper Preheater cylinder

※structural features:

★preheat roller accord the pressure container national standards,and enclose the pressure container certificates and inspection certificate.

★Each roller surface after grinding precision grinding and dealing with hard chrome plating, Surface friction is small, durable。

★electromotion adjustment angle, and angle can rotation adjustment the preheat area in the range of 360°。

★adopt two-stage reducer to adjust angle, and it has the function self-locking。

★Preheat roller head using the butterfly design, with steam heating。

※technical parameters:

1 Effective width:1800mm

2 diameter of preheat roller:¢900mm

3 angle adjustment range:360°rotation

4 angle shaft diameter:¢110mm×2

5 steam temperature:150-180℃

6 steam pressure:0.8-1.3Mpa

7 equipment size:Lmx3.3*Wmx1.1*Hmx1.3

8 single weight:MAX2000Kg

9 working power:380V 50Hz

10 Motor power:250W short(S2)working system

SF-320C Fingerless Type Single Facer

※technical parameters:

1 effective width:1800mm

2、operate direction:left or right(Determined in accordance with the customer’s facility)

3、design speed:150m/min

4、range of temperature:160—180℃

5、air source:0.4—0.9Mpa

6、steam pressure:0.8—1.3Mpa

7 equipment:Lmx3.5*Wmx1.7*Hmx2.2

8、single weight:MAX 7000Kg

※Roller diameter parameters:

1、corrugated roller:up¢320mm down¢316mm pressure roller:¢324mm

2 、glue roller:¢242mm fixed paste roller: ¢140mm preater roller:¢402mm

※powered motor parameters:

1 main frenquency drive motor:5KW rated voltage:380V 50Hz Continuous (S1) working standard

2、suction motor:11KW rated voltage:380V 50Hz Continuous (S1) working standard

3、glue reducer:100W rated voltage:380V 50Hz Continuous (S2) working standard

4、glue gap motor:250W rated voltage:380V 50Hz short(S2) working standard

5、glue pump motor:2.2KW rated voltage:380V 50Hz Continuous (S1)working standard

※structuarl feature:

★adopt hood suction structure,matched high pressure powerful fan. Gas supply and electrical control cabinet to focus on the same operation, the operating side full cover closed.

★High quality resin sand casting,wall thickness 200mm。Adopt independent gear box, Universal joint transmission structure.

★install the lifting trolly on the conveyer bridge,Need to use the car will tile roll assembly and pressure roller, such as convenient and quick.

★Glue roller unit structure with the overall relocation,Maintenance can sway the machine at the overall maintenance,improve the working efficiency。

★The humidity control apparatus equipped with a spray, so flute type to maintain good stability of deformation, avoid dry。

★Automatic circulation system for glue, two-cylinder pneumatic gluing device, with good cushioning effect.

★Glue department using integrated slide structure,Glue roller surface after grinding engraved with 25 lines and pit-style textured hard chrome plating.

★corrugated roller adopt tungsten carbide dealing,diameter of the main corrugated roller¢ 320mm,Quenched→rough car→bore fine boring→shaft head shrunk-on→welding → tempering to stress→fine cars→coarse grinding→IF quenching→CNC grinding machine grinding→Hard chrome plating,hardness of surface is HRC58degrees。

★Active force variable frequency motor drive, energy efficient, low failure rate。

★Glue wide electric adjust to changes in the width of the paper used。

★Amount of glue size with electric adjustment, touch screen display and operation of the encoder transmission coating gap, high accuracy。

★Power and operating parts with a safety net to ensure the safety of personnel in the operation of machinery。

ZDF conveyor bridge

※structural feature:

★Independent frequency motor lifting mechanism, PVC conveyor belt, a single watt of cardboard into a wavy rule stable。

★All roller surface after grinding hard chrome plated。

★Vacuum adsorption tension control,5-inch suction tube,add regulator valve,air volume stepless adjustable air volume.

★Electric corrective devices II sets,correction baffle double guide column positioning,Screw Driver,positioning fast and accurate , smooth running。

※roller diameter parameters:

up paper roller and tension roller: ¢130mm translation roller:¢180mm

Initiative tension roller ¢110mm guide paper roller:¢85mm

※Power motors and electrical parameters:

1 single facer corrugated paper lift motor:3KW (frenquency) 380V 50Hz Continuous (S1) working standard

2、Bridge adsorption fan: 4KW 380V 50Hz Continuous (S1) working standard

3、The cardboard wide motor: 250W 380V 50Hz short(S2)working standrad

RG-3-900 three triple preheater

※structural features:

★preheat roller accord with the national standard of the pressure vessal,and enclosed the pressure container certificate and inspection certificate。。

★Each roller surface after grinding precision grinding and dealing with hard chrome plating, Surface friction is small, durable。

★electromotion adjustable angle, it can rotated adjust the paper preheat area in the range of 360°。

※technical parameters:

1 Effective width:1800mm

2、preheat roller:¢900mm angle shaft:¢110mm

3、range of angle adjustment:360°rotation

4、diameter of angle shaft:¢110mm×2

5、steam temperature:150-180℃

6、pressure:0.8-1.3Mpa

7、equipment size:Lmx3.3*Wmx1.1*Hmx3.9

8、single weight:MAX6000Kg

9、working power supply:380V 50Hz

10、motor power:250W short(S2)working system

GM-C Double Glue Machine

※Structural features:

★after quenched of the glue roller surface,the hole machining, surface grinding and doing balancing engraved anilox pit type, coating evenly, less consumption of plastic

★glue roller turns is controlled by the frenquency motor,by inverter control ensures glue roller line speed synchronous machine with double machine,they can operate independently。

★electromotion adjustment display the glue amount。Automatic cycle for glue, glue avoid sedimentation, viscosity stability。

★Pneumatic structure platen gap by electric tuning。On the next floor are made independent variable frequency motor drive。

★take the speed signal of the double facer,so as to synchronous operation with it. Man-machine interface display, easy operation

★amount of glue automatic adjustment control,amount of glue automatic adjustment with the produce speed, in automatic mode, you can also get in manual tuning.

※ technical parameters:

1 effective width:1800mm

2、operation direction:left or right(Determined in accordance with the customer’s facility)

3、highest design speed:150m/min

4、air source system:0.4—0.9Mpa

5、temperature range of the preheater:150—200℃

6、steam pressure:1.12—1.3Mpa

7、equioment size:Lmx3.3*Wmx1.4*Hmx2.7

8、single weight:MAX40000Kg

※Roller diameter parameters:

1、glue roller:¢269mm Fixed paste roller:¢140mm

2、bottom preheat roller:¢402mm up preheat roller:¢374mm the paper roller:¢110mm

※Power motors and electrical parameters:

1、glue roller initiative frenquency motor:3KW 380V 50Hz Continuous (S1) working standard

2、glue amount adjustment reducer: 250W 380V 50Hz short(S2)working system

3、pressure roller gap adjustment motor: 250W 380V 50Hz short(S2)working system

4、glue pump motor: 2.2KW 380V 50Hz Continuous (S1)working system

SM-C Type Double Facer

※Structural features:

★Heating plate surface by grinding treatment,hot plate width600mm,a total of 14 pieces heating plate.

Preheat board is made of contactor board, in accordance with the national standrads of pressure container, enclosed the pressure container certificate and inspection certificate.

★Hot plate using the touch plate design structure. Plate movements using pneumatic spring-type structure.

★On both sides about conveyor belt deviation adjustment adopts automatic adjustment,2 sets of the conveyor belt tensioning system,one set is manual(fine tuning)、the other is pneumatic adjustment(high speed)。

★Thermal pipe heating plate temperature control points seven sections with temperature display.

★up cotton belt with double cylinder S cotton belt tensioning device。

★bottom cotton belt with s-shaped correction manually tensioning mechanism, structure simple and practical,under with manual fine-tuning.

★Drive roller coated with attached wear-resistant rubber ,showed a herringbone structure,With a high, ensure smooth cardboard output.

★Main drive motor for frequency conversion motor,low-speed torque,wide speed range ,reliable, and easy maintenance.

★hot plate internal for partition isolation structure,s-shaped flow of steam,Steam, water separation function significantly improves the utilization of steam。

※technical parameters:

1、temperature requirment:160—200℃ steam pressure:0.8-1.3Mpa

2、air source pressure:0.6—0.9Mpa

3、Cooling stereotypes length:4m Heating plate quantity:14 pieces

4、hydraulic system pressure:6—8Mpa

※roller diameter parameters:

1 up drive rubber roller diameter:¢700mm bottom drive rubber roller diameter: ¢400mm Wear rubber Outsourcing

2、Former follower with roller diameter:¢270mm After setting belt driven roller diameter:¢186mm

3、Pressure belt roller diameter: ¢70mm Shaping roller diameter:¢86mm

4、The belt tension roller diameter:¢130mm The roll diameter with detuning:¢124mm

5、Under the belt tension roller diameter:¢130mm Entrusted with the roll diameter under the belt:¢130mm

Note: All the roller surface after grinding are hard chrome plated。

※Power motors and electrical parameters:

1 Main drive motor power:30KW 380V 50Hz Continuous (S1) working standard

2、Hydraulic station motor power :2.2KW 380V 50Hz Continuous (S1) working standard

ZQS Thin Knife Slitting

※structural feature:

★Overcome the conventional type of pole, cutting pressure lines appear when collapsed cardboard cut phenomenon, cutting board smooth, quality has improved significantly。

★the whole machine can remove left and right,cycloid reducer to adjust。

★Cutter and easy to adjust the pressure line, the error ± 0.5mm, automatic sharpening device, you can achieve timing Brothers, with intermittent Brothers and other features.

★the machine adopt five knives eight lines,the blade is made of tungsten alloy steel, the using life is not less than 3 million running meters。

Technical Parameters:

1、effective width:1800mm

2、The maximum mechanical speed:100m/min

3、Mechanical configuration: 5knives 8lines

4、The minimum width of the cutter:135mm

The maximum width of the cutter:1850mm

※Power motors and electrical parameters:

1、Line cutter line motor:0.4KW

2、Knife wheel drive motor:5.5KW

NC-150 NC Cutter Helical Knives

※structural feature:

★it can store 200 units orders,replace the cutter specifications quickly and accurately,changing orders without stop,And enables networked computers to facilitate production management.

★Knife shaft drive gears are precision forged steel induction hardening, backlash-free transmission, advanced keyless connection, high transmission accuracy。

★Cutting machine adopts inlaid front steel blade knife spiral structure, serrated knife. scissors, shears, shear force, long blade life。

★around feed rollers are used the sun gear platen way, smooth delivery, pressure evenly, easy to crush plate board or cause blockage。

★This model is the braking energy storage (non-dynamic braking), so the energy consumption in the production process, the average electricity consumption is 1/3 of an ordinary NC cutting machine, saving more than 70% power to reach the goal of saving money .

★Precision adjustable no gap gear to ensure precise blade engagement, running balance。

★Using an independent oil pump and filter with two copper distribution in each gear position oil, lubrication and cooling。

★Knife roller: fine quality forged steel material, the balanced, with good stability.

※technical parameters:

1、effective width:1800mm

2、operation direction:left or right(determined to the customer’s factory)

3、highest machinery speed:150m/min

4、Mechanical configuration:computer-control helical cross cutter

5、Minimum cutting length:500mm

6、Maximum cutting length:9999mm

7、Precision of cutting paper:uniform ±1mm,non-uniform±2mm

8、equipment size:Lmx4.2*Wmx1.2*Hmx1.4

9、single weight:MAX3500Kg

※Roller diameter parameters:

1、Cross on the knife shaft center distance:¢216mm

2、Before the lower conveying roller diameter ¢156mm

3、After the lower conveying roller diameter: ¢156mm

4、The front of the platen roller diameter: ¢70mm

5、The front of the platen roller diameter: ¢70mm

Note: After all have been grinding rollers, hard chrome plated at (on except under the knife shaft) dealing。

※Power motors and electrical parameters:

1、main drive motor power:18.5KW Full AC synchronous servo

2、Before feeding motor power:3KW(Frequency Control)

3、Oil pump motor power:0.25KW

DM-DL1800 Automatic Large Gantry Stacker

※Structural features:

★Five sections using high-strength belt conveyor,Frequency loop control,Precision Auto Points,smooth delivery,rapid separation and delivered to the Ministry of basket gantry。

★sun gear press paper does not do damage to the cardboard.carbon fiber press paper is extremely resistant .

★Block car with the order structure,automatic adjustment,You can order the size of the fragmented,staggered stacking。

★Ministry basket outfeed nylon plastic caterpillar output, does not damage the backing paper。

★Elevator servo control gondola lift,rational counterweight structure,optimal energy efficiency,After the basket outfeed,Transfers power from the platform to the next step of the crawler。

|

Type |

DM-DL1800 |

|

|

The largest collection of paper width |

1850mm |

|

|

Collection of paper length |

Standard:500~3500mm(Can be customized) |

|

|

Logistics roller |

Can be configured according to the order |

|

|

Lateral transport mode |

Modules belt |

|

|

Stacking height |

1700mm |

|

|

Maximum production line speed |

200m/min |

|

|

Dimensions |

Length × width × height:20000×3200×2800mm |

|

|

Total weight |

12T |

|

|

Ø System parameters |

||

|

Position machine |

Taiwan WEINVIEW or MCGS TONTEKColor touch screen10.4” |

|

|

Lower machine |

Performance of Taiwan DELTA SeriesPLC |

|

|

Lift Control |

AC servo controller |

|

|

Frenquency machine |

Taiwan delta |

|

|

Low-voltage electrical |

CHNT、schnerderLow-voltage electrical |

|

|

Ø Power Parameters |

||

|

Conveyor roller drive |

RV reducer:3kw×5 |

|

|

Horizontal driving basket |

Gear reducer: 3KW×2 |

|

|

Paper stop car drivers |

RVreducer:0.75KW |

|

|

Lifting drive |

Worm Reducer:15KW |

|

|

Total power |

about30 KW |

|

※Electrical appliances Configuration

|

NO |

Name |

Type brand |

QTY |

company |

remark |

|

1 |

Air Switch |

2 |

CHNT |

||

|

2 |

Frenquency machine |

5 |

delta |

(taiwan)3.7KW |

|

|

3 |

Frenquency machine |

1 |

delta |

(taiwan)2.2KW |

|

|

4 |

Frenquency machine |

2 |

delta |

(taiwan)15KW |

|

|

5 |

PLC |

1 |

delta |

(taiwan)series PLC |

|

|

6 |

Contactor |

Schneider |

|||

|

7 |

Switching Power Supply |

NESSeries |

3 |

MW |

(taiwan)DC24V |

|

8 |

Fan |

6 |

JY-FAN |

(China ) |

|

|

9 |

Indicator |

XBSeries |

8 |

Schneider |

(France) |

|

10 |

Switch |

ZBSeries |

7 |

Schneider |

(France) |

|

11 |

Emergency stop switch |

ZBSeries |

5 |

Schneider |

(France) |

|

12 |

With lamp reset button |

ZBSeries |

12 |

Schneider |

(France) |

|

13 |

Without lamp reset button |

ZBSeries |

9 |

Schneider |

(France) |

|

14 |

Two reset operation lever knob |

3 |

Schneider |

(France) |

|

|

15 |

HMI |

10.4Inch |

1 |

WEINVIEW |

(taiwan) |

|

16 |

Encoder |

E-004A |

5 |

NEMION |

(Japan) |

|

13 |

Encoder |

E-003 |

1 |

NEMION |

(Japan) |

|

14 |

Photoelectric switch |

E-035A |

3 |

OMRON |

(Japan) |

|

15 |

Trip switch |

XCE-145 |

6 |

TEND |

(taiwan) |

|

16 |

Photoelectric switch |

E-069 |

1 |

OMRON |

(Japan) |

|

17 |

Bell |

1 |

(China ) |

||

|

18 |

Three-color lights |

1 |

(China ) |

||

|

19 |

Red lights |

1 |

(China ) |

||

|

20 |

Pull the emergency switch |

1 |

(China ) |

ZJZ Glue Station System

※Structural features:

★provide the starch adhesive to the corrugated single facer ,two glue machine and some other gluing equioment.

★Horizontal glue machine can meanwhile matched withmain body glue and carrier glue, and mixing, glue large。

★Making room storage barrels adhesive solution was to use the glue pump rubber equipment storage barrels, adhesive solution for equipment。

★Storage barrels, plastic barrels with mixing device, avoid glue solution precipitation agglomerate。

★System unit with carrier vessel, main tank, storage tank, and send the glue pump, the back glue pump, etc。

★glue system adopt glue cycle,rest glue go back to the glue square cylinder,Liquid level float automatic control,the back glue a bucket of glue liquid being beaten back with glue equipment storage bucket,cycle for glue,Save the glue solution,prevent the glue solution in the rubber plate pasting and caking precipitation.

★Work has been completed, the residual gum dividend total pipeline with rubber equipment rubber pumped back rubber room storage barrels, for next time use。

★Responsible for technical guidance, teaching adhesive dispensing process。

※technical parameters:

1 Horizontal body glue mixer: one

2、Carrier glue mixer:one

3、Storage glue mixer: one

4、Plastic buckets on double coater: one

5、Two coating machine back plastic buckets :one

6、Plastic buckets on single machine :two

7、Single machine back plastic buckets: two

8、Lose glue dispensing pumps: four

※glue barrel diameter parameters:

1、Horizontal body glue mixer:1250mm×1000mm×900mm

2、Carrier glue mixer diameter: ¢800mm×900mm

3、Diameter plastic bucket on Double Glue:¢800mm×1000mm Plastic buckets on single machine:¢800mm×1000mm

4、Storage tank diameter: ¢1200mm×1200mm

※Power motors and electrical parameters:

1、Horizontal body glue mixer: 3KW 380V 50Hz

2、Carrier glue mixer: 2.2KW(Ordinary three-phase) 380V 50Hz

3、output plastic pump motor : 2.2KW(Ordinary three-phase) 380V 50Hz

4、Storage Tank Motor 1.5KW(Ordinary three-phase) 380V 50Hz