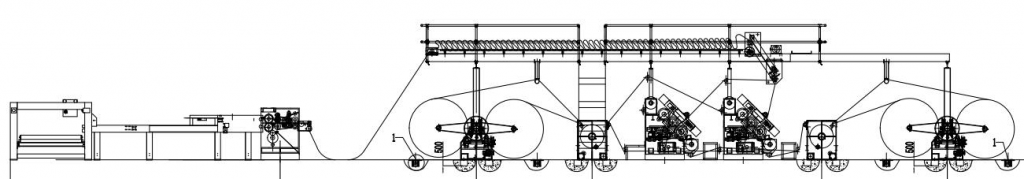

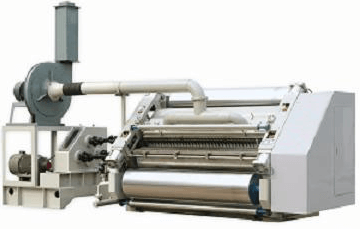

1600-2 LAYER CORRUGATED CARDBOARD PRODUCTION LINE

Design. Speed 150m/min | Working Speed120m/min

| NO. | COMMODITY NAME | QTY |

| 1 |

1600mm – Hydraulic Shaftless Reel Stand ( with 2 feeding track & trolley) |

2 SET |

| 2 | 1600mm – Ø600 Pre-heater | 2 SET |

| 3 |

1600mm – 320B Fingerless Type Single Facer ( Vacuum absorbable feeding; Electric adjust the glue width ; Gimbal driver system. drive motor with frequency inverter) |

1 SET |

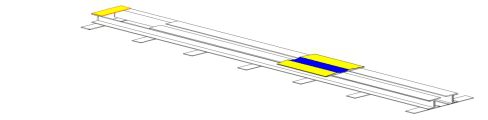

| 4 | Conveying Bridge | 1 SET |

| 5 |

DWX-150 NC Single-face Corrugating Cutting Machine (NC Thin Blade Slitter, Slitter Scorer – Electric Adjustment for Slititng knife , Down Stacking) |

1 SET |

|

Max. paper width: |

1600mm |

|

Max. Width of corrugating roll |

1670mm |

|

Design Speed of machine |

150m/min |

|

Working temperature |

220-280 degree |

|

Flute TYPE: |

As your requirements |

|

Electric power: |

40kw |

|

Power requested: |

415V,50Hz,3-phase |

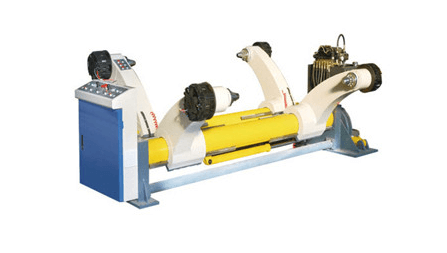

►Spec of Hydraulic:

1,Working Pressure(mpa):16-18mpa,

lift hydraulic cylinder:Φ100×440mm,

Clamping hydraulic cylinder: Φ63×1300mm

Power Motor for Hydraulic Station:3KW –415V — 50Hz

Magnetic Valve Voltage:415V 50HZ

Hydraulic Reel Stand

►Structure and Features:

1,Reel paper lift-lower, clamp, loosen, movement, contra position operated by hydraulic.feeding kraft/reel paper quickly.

2, Brake: multiple-point brake.

►Spec of stand:

1, Reel Stand driven by hydraulic

2, Kraft paper range:

Width: Max: 1600mm Min: 800mm

Diameter: Max: Φ1500mm

Main Shaft Dia.: Φ242mm

Max Weight:3000Kg(One side)

3, Pneumatic Source Pressure(Mpa): 0.4—0.8Mpa

Kraft Paper Feeding Ground Rack & Trolly

►Structure and Features :

1, To feed the kraft paper to reel stand.

2, The whole body of rack is under the ground, main frame: Model 14 channel steel with ¢ 20mm drawing bar weld together,overall length 6000mm.

3, Two racks for one reel stand to feed the kraft paper at both side.

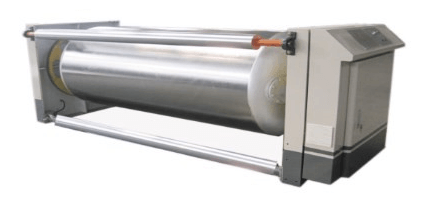

Preheater

- The preheater roller is under the stander of the 1st class(grade) pressure vessel of the national.

- All the surfaces of every rollers have been grinded with high accuracy and chromed plated to less the resistance of paper preheating, long service of using life.

- Electric to enlarge the preheating area, preheating area can be in 360° to adjust the preheating Area.

►Common Spec:

1, Working Width: 1600mm

2, Diameter of the Preheater cylinder:Φ600mm

Preheating adjusting area by electric: 360°

Diameter of the roller for Preheating adjusting area by electric:Φ85mm

3, Steam temperature: 150-200℃ Steam pressure: 0.8-1.3Mpa

4, Working Power:415V 50Hz

5, Power:250W Short Time(S2) Working Type

Corrugated Rollers:

|

Diameter |

Down Roller:Φ320mm |

|

Material |

48CrMo high quality alloy steel, rigidity HRC55°-58° |

|

Processing Way |

The surface of upper-lower roller is plating chrome, annealing, hardening and tempering, surface grinded |

|

Fulte Type |

E Flute |

|

Heating way of the reel paper |

Steam heating |

Preheater Rollers:

|

Diameter |

UP Roller:Φ402mm |

|

Material |

seamless steel tube |

|

Material band or origin |

Tianjin Iron & Steel |

|

All connected by flexible metallic tubes |

|

1600mm- Vacuum Absorbable Feeding Single facer

Glue Rollers:

|

Diameter |

Φ242mm |

|

Processing Way |

Surface of glue roller is grinded, then with 25 line rut type net dot,then plating chrome Surface of glue banlance roller is grinded then plating chrome |

|

Control Way |

Airbags control of the Lifting Up-down |

|

Glue Supply |

Glue circulating system(storage tank+glue pump) |

Press Rollers:

|

Diameter |

Φ324mm |

|

Material |

medium steel (MS)45# |

|

Processing Way |

The surface is grinded then plating chrome, hardening and tempering(With Buffer) |

|

Control Way |

Penumatic cylinder control of the Lifting Up-down |

Common Spec:

|

Style of Transmit cardboard |

Vacuum Cover adsorbable style, Hight pressure Draw fan.with wind control Adjusting & noise deadening device. |

|

Style of Control Roller |

Pneumatic control the upper roller, pressure roller and glue roller |

|

Lubrication |

Anti-high temperature lube to lubricate the Corrugated Roller and Press Roller’s gears |

|

Glue Width Adjusting |

Electric adjusting |

|

Driving Way:With frequency inverter |

|

►Spec of the rollers:

- Paper feeding rollers & tension rollers:Φ127mm transport rollers:Φ110mm

- Main tension drive rollers:Φ127mm paper pass rollers and paper guide rollers:Φ110mm

- Paper feeding rollers with belts:Φ110mm

Note: All the surfaces of the rollers are grinded and then chromed plated.

Conveying Bridge

- The Main Frame is connected with channel steel, and angle steel.

- With Protecting Handrail on both sides and safety pedal, the operation side is installed with safety ladder, to make sure the safety and convenience of the worker.

- PVC feeder belt to transport the single or double face corrugated sheet with corrugated type.

- Vacuum suction tension control, suction pipe with adjusting valve, draw fan power can be adjusted freely.

►Common Spec:

- Working Width:1600mm

- Operation Direction: Left or right(decided by the workshop of customer

►Spec of Motor:

- Single face sheet draw motor: 3kw,Continuous (S1) working Type variable-frequency control

- Draw Fan Motor: 3kw,Continuous (S1) working TypePaper width adjusting speed reducer: 250w Short time (S2) working Type

►Roller Info:

1、Upper Roller of Cutter Knife:¢200mm; With dynamic balance processing

2、Down Roller of Cutter Knife:¢200mm With dynamic balance processing

3、Down Roller of drawing paper:¢156mm With dynamic balance processing

Note: All the surfaces of the rollers are grinded and then chromed plated.

►Spec of Motor:

- Main motor:12.5KW servo motor

- Paper feeding motor:3KW

- Paper delivery motor:1.5KW

- 4. Paper side delivery motor: 0.75KW

DWX-150 Type NC Cutter & Slitter scorer & Down Stacker Specification:

- Keep order 999, touch screen & PLC control system

- Servo system, high-quality servo motor drive.

- Helical cutting knives, Quality gear with high-accuracy grinding, long life knives.

- Stacker with automatic calculation and side delivery. The max. Stacking length 1600mm.

- Adopt tungsten slitter knives, long lift of slitter knives.

- Adopt high quality industrial computer control system.

- Electric adjustment of slitting knife.

►Common Spec:

1、Max. Width:1600mm

2、Operation Side:Left or Right(As Client’s Plant)

3、Design Speed:150m/min

4、Workin Speed:120m/min

5、Equipment configuration:NC Helical Cutter

6、Min. Cutting Length:300mm

7、Max. Cutting Length:9999mm

8、5 groups¢200 circle blade

9、Cutting Accuracy:±1mm(Normal Speed) ±1.5mm(Abnormal Speed)